Understanding the Role of a Manufacturer & Supplier of CNC Machine Parts

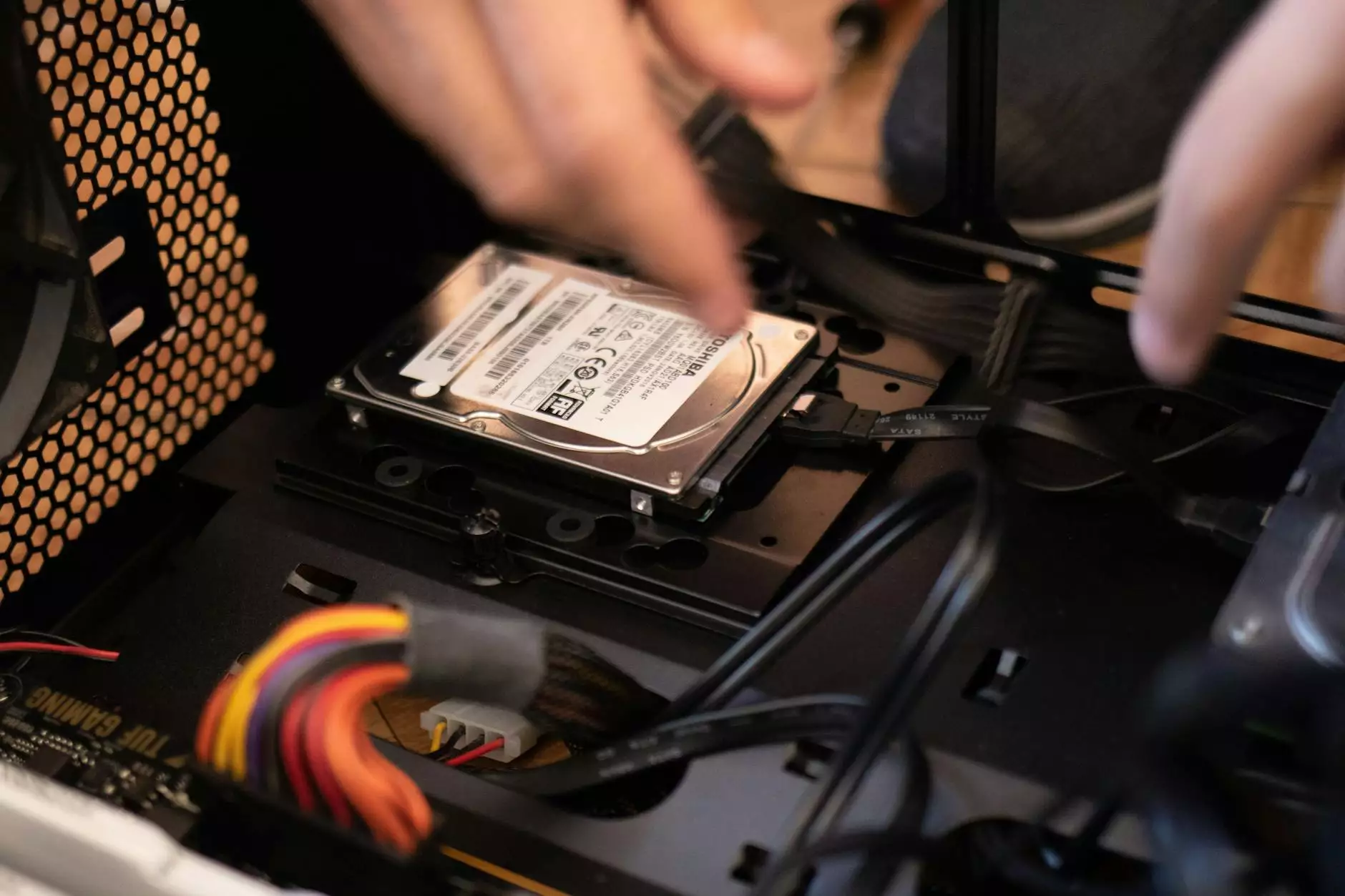

CNC (Computer Numerical Control) technology has revolutionized the manufacturing industry, providing unmatched precision and efficiency in fabricating parts and components. As the manufacturing processes evolve, the demand for a reliable manufacturer & supplier of CNC machine parts has surged, poised to meet the industries' growing needs with high-quality components.

The Importance of CNC Machine Parts

CNC machine parts serve as the backbone for numerous industries, ranging from aerospace and automotive to electronics and heavy machinery. Understanding the significance of these components can provide insights into why sourcing from a competent supplier is crucial.

1. Precision and Efficiency

Each part produced through CNC machining is engineered to meet specific tolerances and measurements. This precision is essential in applications where accuracy is paramount. Additionally, CNC machining allows for faster production times compared to traditional methods, contributing to overall efficiency in manufacturing processes.

2. Versatility and Adaptability

CNC technology can create parts from various materials, including metals, plastics, and composites. Whether you require intricate designs or simple components, a skilled manufacturer & supplier of CNC machine parts can cater to your diverse needs. This versatility makes CNC machining an ideal solution for industries with specific requirements.

3. Cost-Effectiveness

Investing in high-quality CNC machine parts can lead to long-term savings by reducing waste and minimizing rework. Furthermore, an experienced supplier understands how to optimize production processes, offering competitive prices without compromising quality.

Categories of CNC Machine Parts Offered

At DeepMould, we pride ourselves as a leading manufacturer & supplier of CNC machine parts. We offer a variety of products suited for different applications:

1. Machined Components

Our machined components are tailored to meet the requirements of various machinery. These include:

- Shafts: Essential for power transmission in rotating machinery.

- Housing: Providing protection to internal components.

- Brackets: Supporting assemblies and providing structural integrity.

- Adapters: Facilitating the connection between different components.

2. Frame Structures

We specialize in fabricating robust frame structures that serve as the foundation for various machines:

- Custom Frames: Designed to meet specific dimensional and strength requirements.

- Support Structures: Supporting larger machines and equipment for stability.

- Sub-Assemblies: Providing integrated solutions that can be easily installed.

3. Tooling Systems

Tooling systems are crucial for the performance of CNC machines. We offer:

- Tool Holders: Ensuring precise cutting tool alignment.

- Fixtures: Holding components in place during machining.

- Jigs: Aiding in repetitive tasks with high accuracy.

Why Choose DeepMould as Your CNC Machine Parts Supplier?

When it comes to choosing a manufacturer & supplier of CNC machine parts, several factors set DeepMould apart:

1. Commitment to Quality

We adhere to stringent quality control standards, ensuring each product meets the highest benchmarks. By employing advanced machining technologies and skilled personnel, we guarantee quality assurance at every stage of production.

2. Experienced Professionals

Our team comprises experienced engineers and technicians familiar with the latest industry trends and technologies. Their expertise enables us to provide innovative solutions tailored to unique customer requirements.

3. Timely Delivery

At DeepMould, we value our clients' time. Our streamlined production processes ensure that your orders are completed and delivered promptly, allowing you to maintain your operational schedules without delay.

4. Competitive Pricing

Our pricing structure is designed to provide value without compromising quality. We believe that high-quality CNC machine parts should be accessible to businesses of all sizes.

Client Testimonials

Nothing speaks louder than the feedback from our satisfied clients. Here are a few testimonials from businesses that have benefitted from our CNC machine parts:

"DeepMould has been our trusted partner for CNC machine parts for over five years. Their reliability and commitment to quality have made a significant impact on our production efficiency." - James T., Operations Manager at A-Tech Industries

"We appreciate DeepMould's attention to detail and their ability to meet our tight deadlines. Their team is responsive and knowledgeable, making collaboration easy." - Sarah L., Product Development Lead at Innovate Solutions

FAQs About CNC Machine Parts

1. What materials can be used for CNC machining?

CNC machining can work with various materials, including different types of metals (aluminum, steel, brass), plastics, composites, and wood. The choice of material depends on the specific application and performance requirements.

2. How does the CNC machining process work?

The CNC machining process involves designing a part using CAD (Computer-Aided Design) software, which is then converted into a CNC program. The CNC machine follows this program to cut and shape the material into the desired component with precise measurements.

3. Can you provide custom CNC machining services?

Yes, as a proficient manufacturer & supplier of CNC machine parts, we offer custom machining services tailored to your specific needs, ensuring that every part fits seamlessly into your application.

4. What industries do you cater to?

Our CNC machine parts serve a broad range of industries, including aerospace, automotive, electronic, medical, and construction. We understand the unique requirements of each sector and strive to provide suitable solutions.

Conclusion

In the fast-paced world of manufacturing, partnering with a reliable and competent manufacturer & supplier of CNC machine parts is vital for success. At DeepMould, we are committed to delivering high-quality solutions that meet your operational needs and drive performance. With our focus on precision, efficiency, and customer satisfaction, we stand out as a leading choice for all CNC machining requirements. Contact us today to learn more about how we can support your business.